The latest innovation in Rifimpress, the IDRA 2200 ton NOX press with integral vacuum technology was presented at the 31st Assofond Congress, held in Vicenza on 26-27 October 2012 and at the National Conference of the Associazione Italiana di Metallurgia (Association of Italian Metalworkers), held from 7 to 9 November 2012 in Trento.

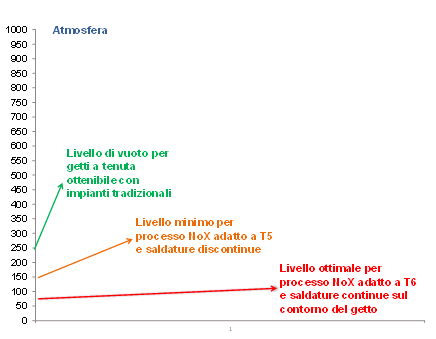

Both presentations were given by Idra’s engineer, Roberto Boni, and have resulted in the initial sampling carried out for the production of motorcycle crankcases which requires high mechanical characteristics using aluminium as the primary alloy, with T6 heat treatment. After the T6 thermal treatment, the crankcases produced with Nox technology, did not show any surfaces blisters other than in a few small areas of some components.

Rifimpress technology offers industrial opportunities that, although requiring particular expedients in the realisation of the mould and increased maintenance in operation, guarantee levels of qualitative stability making it economically competitive. Moreover, the flexibility of the system that can also be used with traditional methods, with and without vacuum, provides customers with the production flexibility that is essential for rising to the challenge of a constantly evolving market.

Enclosed is the presentation given by Roberto Boni at the Assofond Congress: Nox Vacuum casting – Rifimpress